Generative AI in Manufacturing: Smarter, More Efficient Factories

The factory of tomorrow is a masterpiece of innovation — intelligent, perceptive, and brimming with sensor-driven insights. At the heart of this transformation lies in generative AI in manufacturing. Dive into how AI is flipping the script on manufacturing and why it's the secret sauce for tomorrow's factories?

Curious about how AI is reshaping the manufacturing game? Major players in the industry are already tapping into the power of artificial intelligence to supercharge efficiency, precision, and productivity across their operations. Generative AI in manufacturing, in particular, is making waves with game-changing applications like predictive maintenance, supply chain optimization, quality control, and demand forecasting — redefining how manufacturers approach age-old processes.

As reported by VentureBeat, 26% of organizations highlight AI's potential to enhance the decision-making processes that truly matter. Even more compelling, 66% of manufacturers integrating generative AI into their daily workflows admit to an increasing reliance on this game-changing technology, underscoring the rapidly growing momentum of AI adoption across the manufacturing industry.

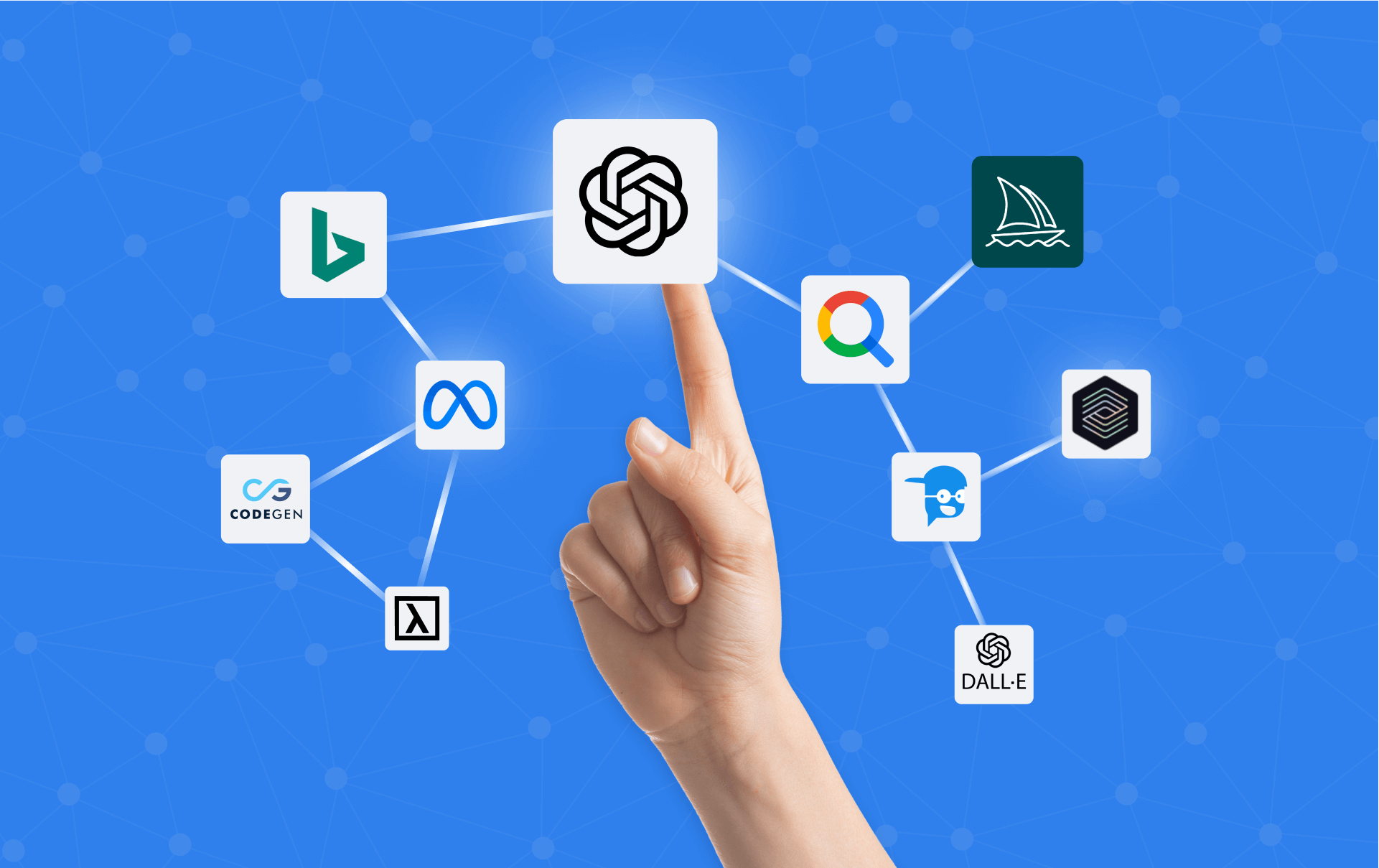

Lastly, the global AI market was valued at $3.2 billion in 2023 and is poised to grow to $20.8 billion by 2028. ☹️ Still, even with all the game-changing possibilities and hefty investments, manufacturers are barely scratching the surface of AI's true potential.

Our blog dives deep into how is AI used in manufacturing with real-world examples of giants harnessing AI (including generative AI in manufacturing) to streamline processes and drive global impact. We will also explore how artificial intelligence is revolutionizing the industry and helping businesses scale to new heights.

What is AI in Manufacturing?

Artificial intelligence in manufacturing is like giving machines a brain — enabling them to tackle humanlike tasks such as responding to internal and external events, and even predicting what is coming next, all on their own.

Imagine a machine that knows when a tool is wearing out or senses an unexpected hiccup (or even a predictable one) and adapts to keep things running smoothly. For instance, acoustic sensors might pick up subtle sounds of belts or gears wearing down, while other sensors track the wear and tear on tools. All this data feeds into predictive analytics models that estimate the remaining lifespan of a component, allowing for timely adjustments before issues escalate.

Modern fabrication machines take it a step further, offering real-time visualization of operations — whether on the machine's interface or remotely through a computer. Operators can see live updates on material levels, power consumption spikes, or even environmental conditions like humidity, which might affect production quality. Some cutting-edge manufacturing systems integrate AI with IoT to enable supply chain adaptability.

Generative AI in manufacturing is a proactive problem solver, an efficiency strategist, and a quality-control pro which sets the stage for a smarter, leaner future in the sector.

🐛 Early bird gets the worm! Unlock your Gen AI potential with a free consultation from Clutch's top-rated Generative AI development company of 2024. We'll dive deep into your unique challenges, goals, and a use case to craft the perfect strategy, tech stack, and roadmap for your Gen AI implementation.

AI in Manufacturing: Examples & Use Cases

We've compiled the top AI use cases in manufacturing for customer service and beyond with real-life examples.

Supply Chain Management

By crunching mountains of historical data and spotting trends that human eyes would overlook, machine learning (ML) algorithms give manufacturers a competitive edge. For instance, an automotive parts manufacturer can leverage ML models to predict demand for spare parts. Instead of juggling excess stock or scrambling to fill orders, they can strike a perfect balance — keeping shelves stocked efficiently while trimming costs.

Walmart, the reigning heavyweight of retail, has revolutionized its supply chain into a high-tech masterpiece powered by AI. Their machine learning algorithms do not just review past sales — they dissect them. By predicting customer demand with pinpoint precision, Walmart ensures products are where they need to be — no empty shelves, no overstock.

Moreover, Walmart turbocharges its logistics with AI-driven routing algorithms, mapping out the fastest, most cost-effective delivery routes.The result is quicker deliveries, lower costs, and happier customers.

Also Read: eCommerce Chatbot for Customer Service Support — a comprehensive guide with everything you need to know about the AI chatbot's features, platforms, benefits, and integrations for eCommerce business.

Collaborative robots (cobots)

Cobots are high-tech teammates that coexist with human operators and amplify their productivity by working side by side. Imagine cobots navigating tight spaces in fulfillment centers, helping pick and pack orders, and identifying objects with laser-sharp precision thanks to AI systems.

Amazon is revolutionizing its fulfillment process with over 750,000 robots working alongside with employees. A standout player in this robotic army is Sequoia, a cutting-edge tool that can identify and store inventory at fulfillment centers a whopping 75% faster than current methods. This slashes order processing times by up to 25% and enhances shipping predictability, giving Amazon the edge to offer more products with same-day or next-day delivery.

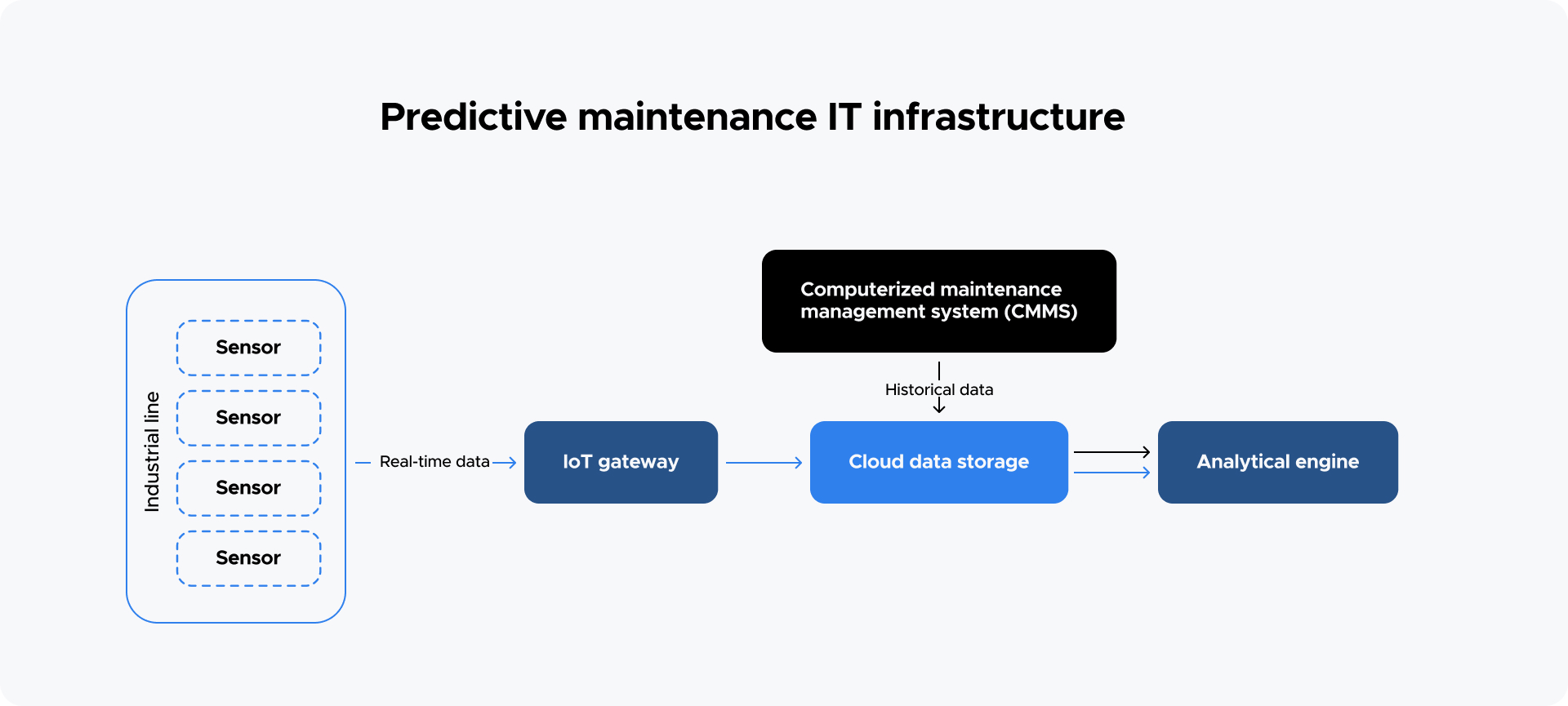

Predictive Maintenance

😱 Did you know poorly maintained equipment can tank your production capacity by 20%? On the flip side, predictive maintenance swoops in as a game-changer, slashing maintenance costs by 5–10% and cranking uptime up by 10–20%.

An AI, armed with predictive analytics and machine learning, and presented as digital twins keeps manufacturing humming by spotting equipment problems before they spiral out of control. Think of it as a virtual assistant of your physical assets, constantly syncing with real-time sensor data. These twins simulate your equipment's behavior, analyze patterns, and sniff out anomalies like Sherlock Holmes for your factory floor.

👋🏻 Say goodbye to the old trial-and-error approach — we've got the intelligence and tools to transform your operations. Ready to elevate your manufacturing game?

For instance, Ford created digital twins for every process step, from design to assembly. Ford's digital twins monitor their manufacturing facilities to pinpoint energy losses and suggest energy-saving tweaks. They predict equipment failures and optimize the entire production line.

NVIDIA utilizes advanced machine learning algorithms which helps to analyze vast datasets related to component architectures. This approach enables them to anticipate potential issues with future chip designs and identify failure points well in advance.

New Product Development

AI is flipping the script on how manufacturers dream up, design, and deliver new products. From market trends to customer quirks and competitor strategies, machine learning algorithms sift through the noise to spotlight actionable insights. With these insights, manufacturers can craft products that meet high market demands.

For example, the global sportswear giant Adidas uses AI to revolutionize how they design and launch products. With its SPEEDFACTORY initiative, Adidas combines AI-driven data analytics with robotics to create sneakers tailored to specific market trends and customer preferences. By analyzing data from social media, purchasing patterns, and even athletic performance, Adidas can predict what consumers want before realizing it themselves.

Furthermore, AI in manufacturing doesn't just stop at ideation — it plays a critical role in production. Using generative design algorithms, Adidas rapidly prototypes shoe designs, cutting down development cycles from months to mere weeks, reducing waste, and creating products that feel like they were custom-made for their audience.

Quality Assurance

With computer vision algorithms in the driver's seat, manufacturers can now analyze images or video streams of products and components to spot defects, anomalies, or deviations from quality benchmarks with laser-sharp precision — far outpacing what even the sharpest human eye could catch.

Take Foxconn as a prime example. By weaving AI and computer vision into their assembly lines, they have completely flipped the script on quality control. These AI systems glance at components and scrutinize them, processing images and videos in real-time to sniff out even the tiniest flaws in electronic parts.

Anomaly Detection

By feeding manufacturing data into deep learning algorithms, the system becomes a master at spotting even the most subtle surface imperfections and deformations in production. The more data you feed it, the sharper its vision gets.

The results speak for themselves. With AI-powered computer vision, manufacturers can expect:

- A 95% defect detection rate, leaving little room for error

- Inspection time was slashed by 25–90%, speeding up the process while maintaining precision

- A 30–80% boost in inspection accuracy, catching issues others might miss.

Airbus integrates smart sensors into its manufacturing processes, keeping an eagle eye on conditions like temperature, pressure, and other critical factors. These sensors collect data and are on the lookout for potential glitches in the system.

If something goes awry, anomalies appear, and the parameters fall outside the designated safe zones, the sensors trigger a shutdown, shifting the workload to other machines. This proactive approach boosts machine longevity by 20–40%, saving Airbus millions in repairs, replacements, and downtime.

Demand Prediction

By tapping into AI, businesses can dive deep into historical sales data, market trends, and external variables. Transforming this raw information into crystal-clear insights allows them to predict demand shifts with remarkable accuracy and fine-tune production schedules in real-time, ensuring they never face the dreaded stockout or get buried under excess inventory.

BMW uses AI in manufacturing to predict demand for specific car models across different markets. By analyzing everything from regional buying trends to economic factors, the automotive giant can adjust their manufacturing plans on the fly, ensuring the right cars are produced in the right quantities — without overcommitting resources, keeping operations running smoothly and profits on the rise.

For fashion and apparel manufacturers, AI-driven advancements are reshaping both the factory floor and the retail landscape. Automation in manufacturing not only streamlines operations but also enables brands to adapt swiftly to changing consumer trends through data and demand forecasting. In parallel with these innovations, partnering with specialized eCommerce solutions for fashion brands allows apparel companies to further optimize their fulfillment, returns, and branded experiences—seamlessly connecting advanced production capabilities with outstanding online customer service.

Caterpillar was grappling with significant supply chain headaches previously, including a lack of real-time inventory visibility, which resulted in both overstocking and frustrating stockouts. By the end of 2021, Caterpillar's backlog had skyrocketed by more than 60%, reaching $23 billion.

To tackle these challenges, Caterpillar deployed an AI-driven system for real-time monitoring and data analysis. This solution enhanced inventory management and refined demand forecasting, resulting in quicker lead times, reduced costs, and a more efficient supply chain.

Effective Documentation with Generative AI in Manufacturing

Gen AI is stepping up the game when it comes to frontline worker documentation. Imagine a tool that provides a one-stop resource for all machine details and standard operating procedures, right at the fingertips of your workers.

Instead of flipping through manuals or waiting for a supervisor, a worker can simply ask the Gen AI tool — either by voice or text — what to do if a machine malfunctions. For instance, if a machine starts overheating, the tool will instantly provide step-by-step instructions on resolving the issue.

Conversational AI for Customer Service

Through conversational AI in manufacturing — chatbots and virtual assistants — AI can answer common questions, guide users through troubleshooting, and manage service requests, all while reducing the need for human intervention. By integrating with existing systems, AI can handle order tracking, maintenance inquiries, and product support across multiple channels, improving response times and customer satisfaction.

We partnered with one of the leading European Industrial Internet of Things for the metalworking industry, with over 80 years in the industry. Its system combines IoT sensors and a cloud platform to monitor coolant levels in real-time, helping prevent costly machine downtime.

To complement this, the company wanted a chatbot for manufacturing that would elevate their customer service experience and align with their brand image. With a small customer service team and a diverse international customer base, they needed a multilingual solution that could anticipate customer inquiries.

We collaborated to create a chatbot with 7 languages, capable of handling over 100 FAQs and managing troubleshooting, setup guidance, and subscriptions. The bot not only provides answers but can also create and track support tickets. When it doesn’t have an answer, it offers relevant Google search results. Integrated with Dynamics 365, the chatbot supports both the mobile app and web platform, giving customers a seamless self-service experience.

More use cases for manufacturing

Why AI Is a Game-Changer for Manufacturing

From turbocharged workflows to cutting-edge innovation, here is how AI brings next-level benefits to manufacturing.

👋🏻 Bye-Bye Paperwork, Hello Automation

Paperwork is the bane of manufacturing efficiency — slow, error-prone, and draining valuable time. But AI and machine learning (ML) are stepping in with a killer combo: robotic process automation (RPA). Imagine bots that can breeze through mountains of purchase orders, quality reports, and other repetitive tasks, extracting and processing data faster than any human could.

For instance, Whirlpool isn't just automating assembly and material handling. The company uses RPA to ensure its paperwork game is on point. The result is obvious: fewer errors, faster processes, and consistent quality control.

🚄 Speed That Leaves You in the Dust

AI-driven automation is the ultimate efficiency booster. It takes over repetitive tasks that would otherwise bog down human workers, eliminates errors, and fine-tunes workflows. Imagine production lines that practically run themselves — raw materials glide in, finished products roll out, and the process hums like a well-oiled machine.

📉 Slashing Costs Without Cutting Corners

AI in manufacturing doesn't just save money — it is the MVP of lean manufacturing. Predictive analytics catches issues before they snowball into expensive repairs. Energy optimization systems cut down on power bills. And automated quality checks ensure zero waste by catching defects early.

🔮 Smarter Decision-Making, No Crystal Ball Needed

Artificial intelligence in manufacturing processes more data in a day than a human could in a lifetime, giving managers the power to make decisions based on hard facts. It basically lets you run "what-if" scenarios to test new ideas without risking downtime.

👷🏻♂️ Safety Gets a High-Tech Makeover

AI in manufacturing isn't just about making machines more intelligent. It is also about keeping humans safer. Collaborative robots can handle back-breaking or dangerous tasks, letting workers focus on safer, higher-value activities. And with AR (augmented reality) and VR (virtual reality) overlays guiding employees through complex tasks, safety and precision get a serious upgrade.

VR solutions allow factory workers to simulate scenarios like equipment malfunctions or assembly line breakdowns. For example, operators can practice responding to a conveyor belt jam or a robotic arm malfunction in a virtual environment, honing their troubleshooting skills without risking downtime or damage to actual machinery. This hands-on, immersive training ensures employees are prepared to handle real-life disruptions swiftly and effectively.

How to Implement AI in Manufacturing Operations?

Embarking on the AI journey in manufacturing requires a solid game plan and a well-structured approach. To get AI humming smoothly in your factory, follow these steps to ensure you are set up for success:

#1. Identify Key Areas for AI Application

Start with a deep dive into your operations — what is slowing you down? Where's the bottleneck? Whether it is predictive maintenance, fine-tuning quality control, or supercharging inventory management, artificial intelligence in manufacturing is a powerful tool for solving actual pain points. The trick is knowing where it'll have the most significant impact. Focus on the areas that will move the needle for your business.

#2. Collect and Organize Data

Artificial intelligence in manufacturing relies on accurate and relevant data. Get your data house in order by ensuring systems are in place to capture and store insights from every corner of your operation — from machines and sensors to worker inputs. The cleaner and more relevant your data, the sharper the AI's decisions and predictions will be.

#3. Partner Up with the Reliable AI Experts

A one-size-fits-all product does not exist. While many AI providers pitch off-the-shelf solutions with promises of instant fixes, be wary of quick-fix traps. A generic predictive maintenance model or cookie-cutter automation might seem like a shortcut, but it could wind up costing more in the long run.

Instead, seek out a generative AI development company that understands your specific pain points and can tailor solutions to your exact needs. Custom AI takes time to develop, but once it is deployed, the payoff is worth it — think of it as a long-term investment that scales with your business.

#4. Get Your Feet Wet with Pilot Projects

Before going full throttle, start small. Test AI with a few pilot projects to measure the real-world impact. This allows you to gauge effectiveness, identify bumps in the road, and make adjustments without risking your entire operation. Think of it like a prototype run before going into mass production — only this time, it's the AI that is being fine-tuned.

#5. Get Your Team on Board with Training

You can't just throw AI into the mix and expect everything to run like a well-oiled machine. Develop training programs that empower your team to not only understand the technology but also work seamlessly alongside it. When humans and AI are in sync, productivity and innovation hit new heights. Plus, your employees will feel more confident and capable, rather than overwhelmed by high-tech updates.

#6. Monitor and Optimize

AI isn't a set-it-and-forget-it solution — it needs regular tune-ups. Once you've rolled out your AI solution, keep an eye on performance. Leverage analytics and user feedback to make real-time improvements, ensuring the tech continues to evolve and align with your ever-changing needs. The goal is to make AI an ongoing driver of progress, not a static tool gathering dust in the corner.

How BotsCrew's Custom AI Solutions Can Help With Achieving Your Strategic Goals in Manufacturing

To truly unlock the power of AI in manufacturing, you'll need a trusted partner who knows the ropes. Enter BotsCrew — experts in crafting state-of-the-art AI solutions tailor-made for the manufacturing world.

As the manufacturing sector evolves faster, BotsCrew stays at the forefront of innovation, creating custom AI solutions that shake up standards across the US, UK, Australia, UAE, and beyond. By teaming up with us, manufacturing businesses can tap into the full potential of AI and machine learning, revolutionizing their operations and gaining the edge in today's fiercely competitive marketplace. Let's put your business on the fast track to success!

🤔 Want to implement AI but unsure of how to use it effectively? Facing difficulties in transferring skilled labor expertise? Want to enhance efficiency and productivity? You can solve these challenges with us. Accelerate your manufacturing transformation.