Faster, Smarter: The Power of AI in Supply Chain & Procurement

Ever wondered how top teams use AI in supply chain and procurement to stay ahead and make faster choices? Discover the strategies and insights that are transforming procurement into a smarter, leaner, and more agile function, as well as how to use AI in supply chain management.

While AI's footprint in procurement is still emerging, technologies like predictive analytics, natural language processing, machine learning, and RPA are already reshaping how teams operate — streamlining workflows, strengthening risk management, and accelerating decision-making. Far from being a purely transactional function, procurement is positioning itself as a strategic driver: AI is helping organizations cut costs, deepen supplier relationships, and uncover insights previously hidden in plain sight.

Dive in as we unpack the evolving role of AI in supply chain and procurement and explore how this transformative technology is redefining industry practices, making procurement smarter, faster, and more strategic than ever before.

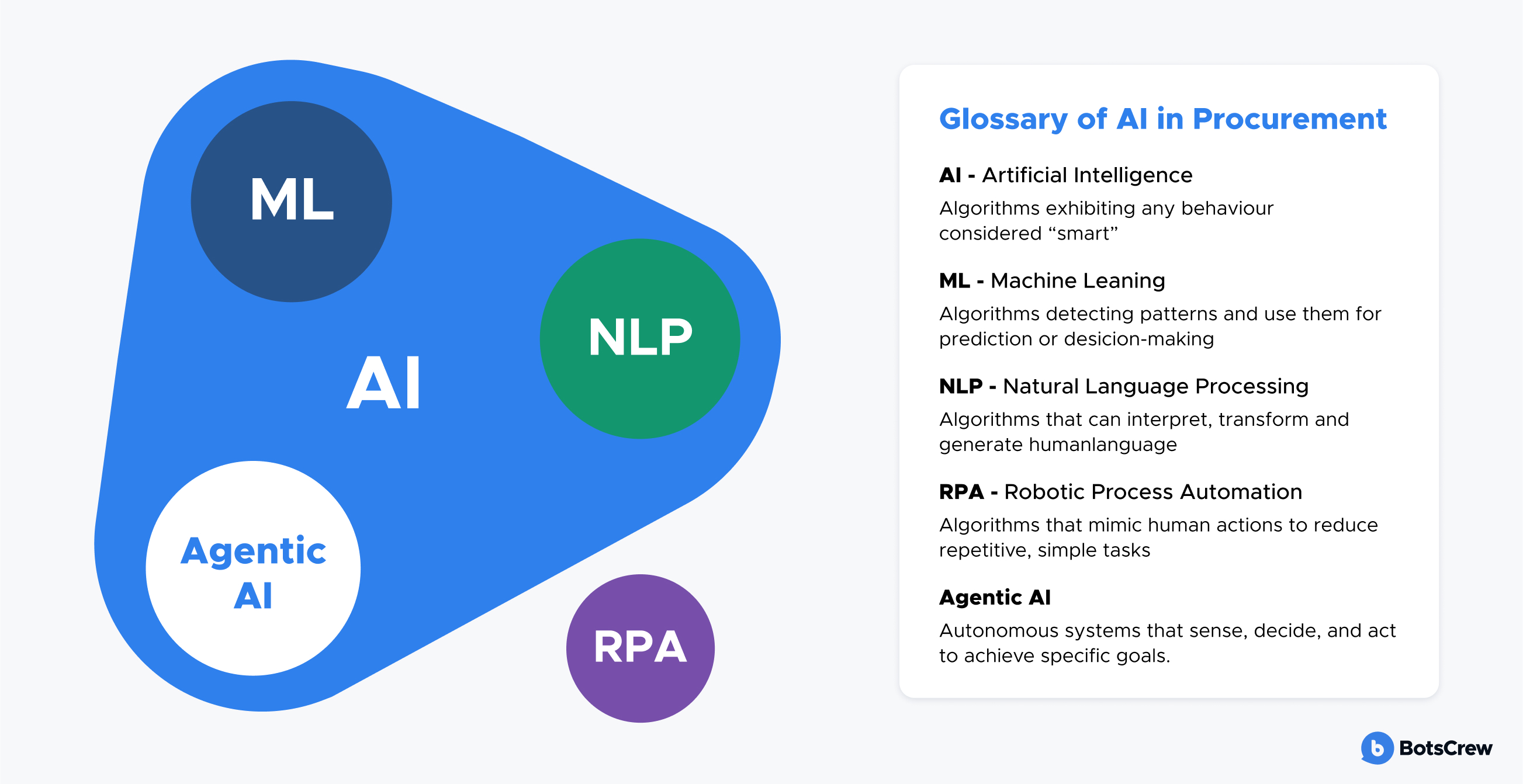

Types of AI Used in Supply Chain & Procurement

A procurement team needs to make decisions every day: which supplier to choose, how to manage risks, and when to reorder stock. For years, the team slogged through manual, repetitive tasks, vulnerable to mistakes — until Artificial Intelligence entered the picture.

— At first, it was Machine Learning (ML) — algorithms that learned from past purchasing patterns, predicted demand, and flagged suppliers at risk of delays.

— Next came Natural Language Processing (NLP). Using it, the team could automatically read contracts, extract key clauses, and analyze supplier emails. The system learned to comprehend human language, extracting meaningful knowledge from piles of documents.

— As their comfort with artificial intelligence in procurement and supply chain grew, they explored Deep Learning (DL) — the next frontier. These advanced algorithms processed complex, unstructured data, identifying hidden trends and even generating draft contracts.

— Robotic Process Automation (RPA) joined the workflow, handling repetitive tasks like invoice processing and order entry.

— Then arrived the game-changer: Agentic AI. Unlike traditional systems, this AI didn't just analyze data — it took action. It made proactive recommendations, suggested decisions, and could execute specific tasks autonomously. The team could now bridge the gap between data and action, moving faster and smarter than ever.

Why Teams Should Leverage AI in Supply Chain and Procurement

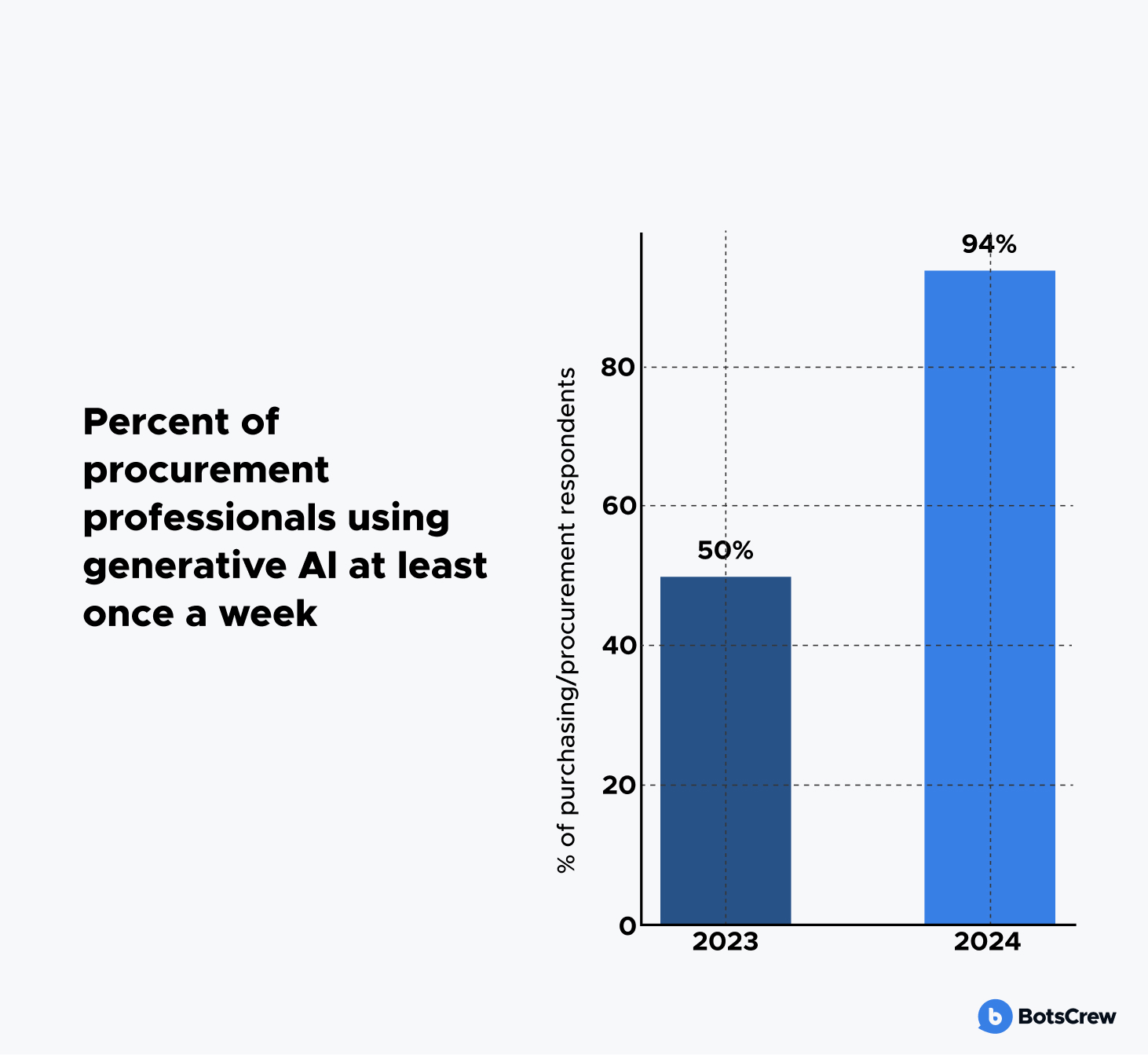

Ever wondered how generative AI drive supply chain transformation? Procurement teams often operate under tight budgets, limited staff, and increasing demands. Every purchasing decision counts, and errors can be costly — from overspending to supply chain disruptions.

Access to reliable, comprehensive data allows procurement to secure high-quality goods and services at the best possible prices, maintain supplier performance, and deliver on customer expectations, all while strengthening the company's competitive edge.

AI emerges as the secret weapon for smarter, faster procurement decisions. By analyzing vast amounts of structured and unstructured data — from contracts, invoices, and purchase orders to emails, supplier reports, and market trends — AI uncovers patterns and insights that would take humans days or weeks to identify. Machine learning models and generative AI in supply chain and logistics are particularly adept at processing this information, helping teams make smarter, faster, and more informed decisions.

According to Deloitte, over 60% of chief procurement officers are already leveraging advanced analytics to drive better outcomes. Organizations that integrate AI effectively see measurable improvements in cost reduction, supplier performance, and procurement cycle times, while also freeing teams to focus on higher-value strategic activities.

Schedule a Consultation with Our AI Experts. Unlock cost savings, streamline workflows, and get a clear, actionable roadmap for integrating AI into your procurement and supply chain processes.

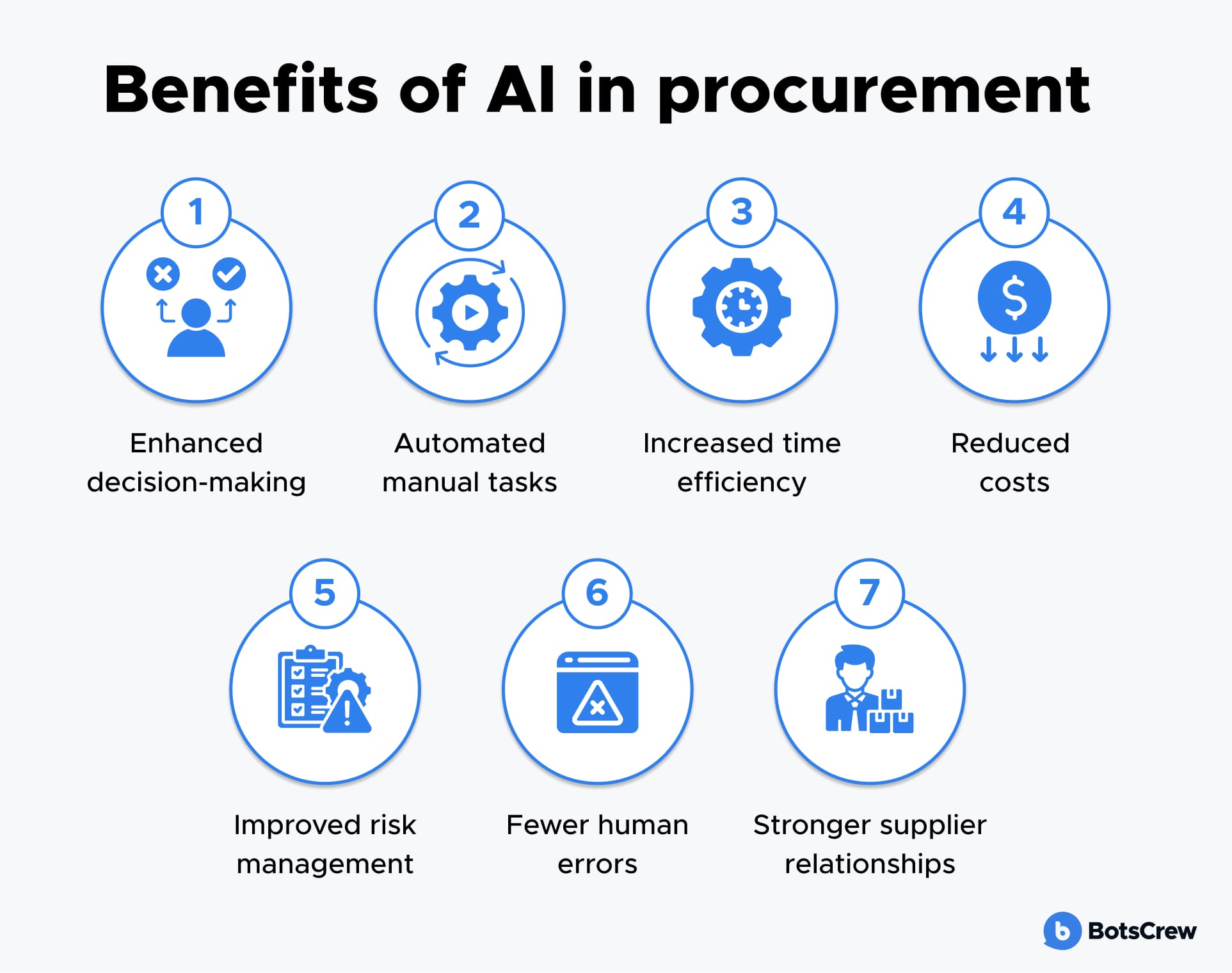

So, how AI is changing supply chain management? AI gives procurement teams a measurable edge — cutting costs, reducing errors, and accelerating decision-making. By automating routine processes and analyzing complex data sets, AI helps organizations improve efficiency, strengthen supplier management, and capture more value from every dollar spent.

Enhanced Decision-Making

Procurement teams often juggle siloed spreadsheets and outdated reports, making decisions on instinct. AI in the supply chain analyzes contracts, invoices, POs, emails, and market data in real time, revealing patterns like sudden price swings or chronic supplier delays. It can forecast demand spikes, supplier performance, and commodity price trends weeks in advance.

Key wins:

— Faster, fact-based sourcing and forecasting

— Early alerts on price changes or supply disruptions

— Measurable savings on every purchase order.

Automated Manual Tasks & Increased Time Efficiency

Procurement teams typically spend half their workweek on repetitive administrative tasks — matching invoices, creating POs, chasing approvals. At the same time, AI in supply chain and procurement and Robotic Process Automation can automate these tasks. Furthermore, according to KPMG (2023), AI can cut time spent on routine procurement tasks by up to 80%, with more than 50% of procurement labor being automatable.

That means with AI in supply chain and logistics, a team that spends 20 hours a week on routine paperwork could reclaim 16 hours for strategic work like supplier negotiations or cost-analysis.

Key wins:

— Fewer errors with AI for supply chain: near-100 % accuracy in invoice/PO matching

— Faster cycle times: approvals and onboarding completed in minutes, not days

— More strategic bandwidth: staff focus on sourcing strategy and supplier collaboration instead of data entry.

Reduced Costs

Hidden tail spend and misclassified purchases quietly drain around 5–10 % of annual budgets. AI in procurement continuously classifies every transaction, enriches spend data with market intel, and flags duplicate or off-contract buys. It also recommends supplier consolidation and contract renegotiation when pricing drifts above benchmarks.

Key wins:

— Continuous cost reduction beyond annual audits

— 24/7 detection of duplicate payments or off-contract spend

— Mid–single-digit percentage savings across total spend.

Improved Risk Management

Supply chains can break overnight from geopolitical events, weather, or sudden regulatory changes. AI in supply chain management scans global news, logistics feeds, and supplier data while NLP tools check contracts for compliance gaps. It predicts which suppliers or regions are high-risk and flags issues before they escalate.

Key wins:

— Real-time risk visibility across the supply base

— Faster contingency planning and crisis response

— Lower legal and financial exposure.

Fewer Human Errors

Manual three-way matching (invoice–PO–receipt) invites duplicate payments and missed invoices. AI automates matching with near-100 % accuracy, flags anomalies instantly, and self-learns from past exceptions.

Key wins:

— Dramatically fewer duplicate or missed payments

— Cleaner books and tighter financial controls

— Less rework for finance and procurement teams.

Stronger Supplier Relationships

Supplier reviews often happen quarterly or annually, leaving blind spots. AI in supply chain management tracks KPIs — on-time delivery, defect rates, responsiveness — and scores each supplier against cost, quality, and reliability. Predictive analytics highlight potential disruptions before they affect production.

Key wins:

— Proactive supplier engagement and joint improvement plans

— Early warnings on performance dips or disruptions

— Better pricing, innovation, and service levels.

Lastly, AI systems are highly scalable and flexible, adjusting to changing business volumes, supplier ecosystems, and market conditions. It integrates new suppliers seamlessly, adjusts to seasonal demand or market fluctuations, and handles increasing complexity without additional manual effort.

This makes AI particularly valuable for rapidly growing organizations or those entering new markets, where procurement complexity can otherwise overwhelm teams.

Generative AI Use Cases in Procurement Across Industries

According to Deloitte, high-performing Chief Procurement Officers are 18x more likely to have fully deployed AI and cognitive capabilities across their procurement functions. And the effort pays off: in every sector, procurement teams face increasing pressure to lower costs, ensure compliance, manage supplier risk, and respond to market volatility — all with fewer resources and faster turnaround times.

We've put together how organizations in different sectors are applying artificial intelligence in supply chain management to create a measurable impact.

Optimize Your Procurement with AI Agents. Streamline your workflows, reduce manual effort, and make smarter, data-driven decisions with BotsCrew AI agents. Take control of your procurement today.

Manufacturing

Manufacturers operate in complex, global supply networks where delays or inefficiencies can halt production. Artificial intelligence in supply chain management delivers actionable intelligence to keep operations running smoothly.

Enhanced Spend Analytics. AI consolidates and analyzes global spend data to identify inefficiencies, eliminate duplicate payments, and find supplier consolidation opportunities. Leading manufacturers report a reduction in direct material costs by using AI-driven spend analytics to spot savings opportunities early.

Contract Lifecycle Management. AI in supply chain management tracks thousands of supplier contracts across geographies, flagging key renewal dates and clauses for renegotiation. It detects value leakage from missed rebates or expiring volume discounts.

Supplier Evaluation & Risk Management. Generative AI in procurement continuously assesses suppliers based on delivery performance, quality scores, and financial health. It also monitors geopolitical or environmental risks that could disrupt production.

Smart Inventory Management. Demand forecasting models and smart inventory management solutions predict usage of raw materials and components, preventing overstocking and avoiding costly production delays. Companies using AI forecasting and inventory optimization have reduced inventory holding costs and excess inventory by about 20%, which helps free up cash tied up in inventory.

Retail & E-Commerce

With thousands of SKUs, suppliers, and daily transactions, retailers benefit from AI-driven automation and real-time insights to keep supply chains lean and responsive.

Procurement Automation. AI automates purchase order creation, invoice matching, and compliance checks — a must-have for high-volume procurement environments.

Guided Buying Experiences. AI guides employees through pre-approved purchase options, ensuring compliance with budgets and vendor policies.

Customer-Facing Chatbots. AI chatbots handle inventory queries, delivery status, and return questions instantly — reducing pressure on support teams. And some retailers using AI-powered chatbots achieved lower customer service costs while improving customer satisfaction scores.

Logistics & Transportation

Logistics companies face a constant challenge: coordinating hundreds of drivers, trucks, and shipments in real time — often relying on manual communication and disconnected systems. This leads to:

- High operational costs due to inefficient workflows

- Delays caused by slow response times

- Limited visibility into driver activity and shipment status

- Overloaded support teams handling repetitive requests.

AI streamlines transportation management by automating communication, validating data, and orchestrating operations end-to-end:

Driver Communication Automation. AI-powered chatbots interact with drivers through familiar channels like WhatsApp, handling check-ins, fuel requests, incident reports, and rescue calls automatically.

Data Validation & Record Updates. AI cross-checks driver-submitted data (e.g., mileage, photos) against historical records via API integrations and updates databases instantly.

Support Ticket Creation. Artificial intelligence in procurement and supply chain triggers Zoho Desk (or similar systems) tickets for cases requiring human review, keeping support focused on complex issues.

Real-Time Notifications. Drivers receive instant updates on approvals or next steps, reducing downtime.

We partnered with Africa's leading logistics marketplace to deploy a WhatsApp chatbot that digitizes truck transportation operations — delivering measurable cost savings, efficiency gains, and last-mile transparency.

The client needed a single platform to manage 200+ daily driver requests (check-ins, fuel requests, incident reports, rescue calls), 60% of which they wanted to automate. The solution also had to integrate with their internal database and Zoho Desk to streamline support.

Our team integrated chatbot with the client's database to validate driver data (e.g., mileage, odometer photos) and update records dynamically, connected chatbot to Zoho Desk to create tickets for cases requiring human assistance, and automated notifications to drivers when requests required review or approval.

Now used company-wide by 500+ drivers, the chatbot provides instant assistance, simplifies workflows, and delivers measurable improvements in efficiency and driver experience.

Hospitality & Food Services

In hospitality, procurement directly impacts profitability and customer experience. AI helps ensure supply reliability and financial accuracy.

Invoice Data Accuracy. Artificial intelligence in procurement and supply chain automates invoice reconciliation, detects discrepancies, and matches invoices with purchase orders and deliveries.

Supplier Communication Chatbots. AI chatbots confirm deliveries, resolve issues, and trigger re-orders automatically, keeping kitchens stocked and reducing downtime, especially during peak service.

Automation in Procurement: 6 Steps to Transform Your Workflow

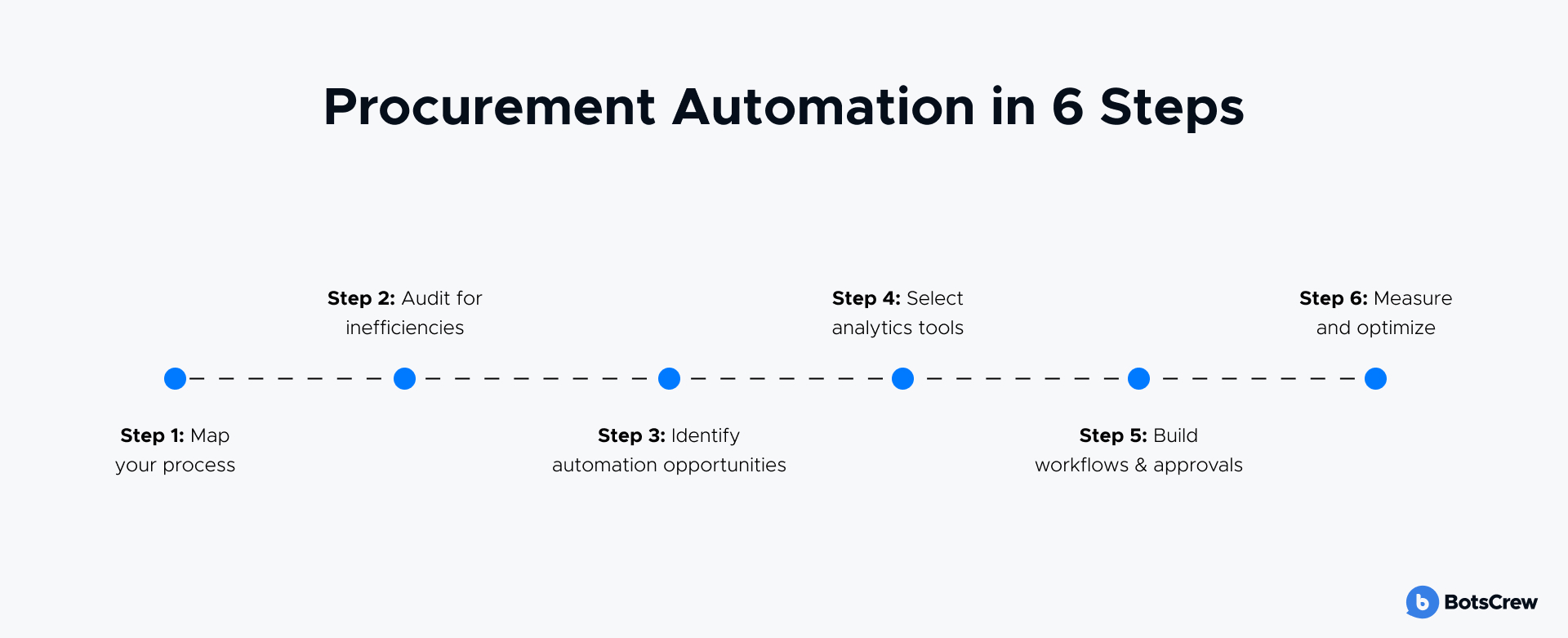

Here is how a typical procurement team transformed its operations in six steps:

#1. Mapping the Current Process

The first step is to understand every twist and turn of the workflow. From requisitions to payments, the team documents each step, identifying redundancies and delays. For instance, teams often discover that 30–40% of their steps are purely administrative — prime candidates for automation.

#2. Auditing Performance

Next, the team measures KPIs: how long does it take to approve a purchase order? How often do invoices get disputed? They benchmark these against industry standards to see where automation could make the biggest impact.

#3. Spotting Automation Opportunities

Repetitive, high-volume tasks are the low-hanging fruit: purchase order creation, invoice matching, contract alerts, and compliance checks. Bottlenecks like manual approvals or paper-based forms can be marked for replacement.

Pro tip: Start small and start with boring problems. Focus on areas like spend analysis, contract management, or purchase order processing. Even automating just one process, like invoice reconciliation, can deliver fast, measurable ROI.

Keep in mind that artificial intelligence in supply chain management excels at focused, narrow tasks — not complex negotiations or nuanced strategy. Identify functions that consume significant time, have predictable outcomes, and impact performance measurably.

#4. Choosing the Right Technology

Time to go shopping — but for software. Think of this like picking a dream team: your automation platform should play nice with your existing ERP, crunch data for sharp analytics, and offer AI smarts without a steep learning curve. Look for tools that:

- Snap into your current systems (no messy rewiring).

- Provide real-time dashboards so you can see bottlenecks before they bite.

- Scale as your procurement volume grows.

Pick tech that is powerful yet user-friendly, so your team actually wants to use it.

#5. Building Workflows and Approval Points

Automation workflows replace repetitive approvals with smart triggers, such as auto-approving purchases under a set threshold. Exceptions can be routed to the right people, and compliance checks can be embedded at every stage.

#6. Measuring Success and Improving

Finally, the team tracks results: cycle times fall, error rates drop, and supplier relationships improve. Feedback from users highlights areas to refine workflows and expand automation.

The Future of Procurement

What is the future of AI in supply chain management? And how AI can be helpful for the future supply chain? The following 10–20 years in procurement are unpredictable, but one thing is clear: AI will continue to reshape how organizations operate.

Analysts agree that the AI applications already in use today — from spend analytics to contract management — will evolve, becoming smarter, faster, and more integrated across procurement processes.

Some tasks are already straightforward to automate. Payment and invoice processing, order placement, and demand management can run efficiently with minimal human input. Others, like vendor selection, negotiation, and supplier management, remain complex, requiring strategic human judgment. Expect AI to gradually take over routine operational tasks first, freeing procurement professionals to focus on higher-value, strategic work.

Generative AI in supply chain management takes this even further. AI agents will not just assist humans — they will collaborate, communicate, and negotiate autonomously with suppliers, other agents, and internal teams. Every interaction will be personalized, context-aware, and proactive. Insights that once took days or weeks to uncover will be delivered in real time, guiding smarter, faster decision-making across all spend categories.

The potential is transformative:

✅ Total Process Automation: Routine approvals, compliance checks, reporting, and operational tasks run without human intervention.

✅ Automated Value Creation: artificial intelligence in procurement and supply chain can identify and act on cost-saving or value-generation opportunities independently.

✅ Full Spend Transparency: Every procurement-related expense becomes visible and accurate, available to stakeholders instantly.

✅ Enhanced Efficiency & Productivity: AI reduces 50–80% of routine work, while even complex tasks requiring specialized expertise can be executed with AI guidance.

✅ Deeper Insights for Strategic Decisions: AI delivers actionable recommendations for sourcing, supplier development, and process optimization.

Procurement will no longer be a series of manual transactions but a data-driven, insight-powered, and highly strategic function. Organizations that embrace AI today will be best positioned to capture tomorrow's value.

Ready to see Procurement AI in action?